What Everyone Ought to Know About Rotary Engraving.

Posted: Thursday, June 2, 2011 at 8:56:05 AM EST by Website Administrator

The application of rotary engraving refers to engraving done with a rotating cutting tool. This is when a particular surface is cut to a set depth creating a groove. The shape of the groove is based on the shape of the cutting tool. This application of engraving can be applied to many materials ranging from acrylics and soft plastics to your soft and hard metals.

This rotating cutting tool is referred to in the industry as a 'cutter'. Many varieties of cutters are produced each for a particular type of surface. Cutters can be separated into two main types.

- Conical Cutters

- Parallel Cutters

Conical cutters produce a 'vee' shaped groove in the surface. Alternatively, parallel cutters produce a box shaped groove with straight walls and a flat bottom. Based on what you are wanting engraved depends on the type of cutter that will be used. The two main types of cutters can be put into five categories depending on their size.

- ACR (acrylic)

- FLX (soft plastics)

- PHN (rigid plastics)

- BAL (soft metals)

- SSS (harder metals)

There are many applications for this technique including engraving stainless steel for mining tags and wherever permanent engraving is required.

Traffolyte is also a popular product, especially for switchboard companies, hospitals and universities. They like their name labels, and diagrams engraved on traffolyte which can only be rotary engraved.

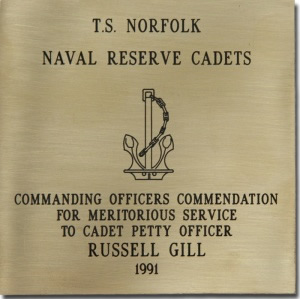

Rotary engraving is also used on switch plates, brass plaques and many fire and safety labels.

Rapid engraving is able to use rotary engraving on many custom applications.

Contact John today to meet your industrial engraving needs.